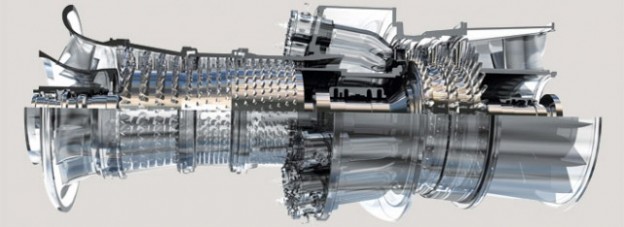

Turn key solution for your gas and steam turbine

The SIPA specialists can provide technical management, project management, project coordination, monitoring, labor, (special)-tools, repairs, spare parts procurement, commissioning up to full EPC for your gas and steam turbines and provide you with a turnkey complete package. We maintain the entire turbine generator unit: controls, auxiliary equipment, transmission and generator as well as combustion and hot gas path components.

Inspection + Maintenance

With a SIPA inspection, you record all relevant data of your unit. This allows you and us to better identify potential issues and identify trends across multiple inspections and protect your equipment from unexpected outages. With our proactive approach to inspections, repairs and maintenance, forced outages will be avoided in the future. Our engineers and specialists work to the highest quality standards, which not only ensures the safety but also the quality of all work carried out. With our SAMS monitoring system, we detect out inspections even faster and more accurately, and ensure security of supply.

Global service

The SIPA team is responsible for the perfect use of your gas and steam turbines worldwide. Our container tools, our global network of suppliers, and our on-site repair capabilities allow fast service even in the most remote locations. Thus you can be sure that we support you anywhere in the world.

System improvements

SIPA can improve gas and steam turbine efficiency and / or your emissions profile. With the latest calculation methods and simulations of your entire power plant fleet we can optimize your operations. We can also upgrade and modify the components of the entire powerplant with FEM and CFD, thereby increasing efficiency and or reliability. Improving the mass flow rate of the intake system and optimizing the compressor efficiency are only a few possibilities. Trust SIPA and its experience. Contact us today for more information.

SGT1000 SGT 2000 SGT 4000 SGT 600